Take you into the world of polyurethane hardeners

Polyurethane hardener usually refers to the component containing isocyanate groups (NCO) in two-component polyurethane products, mainly used in combination with components containing active hydrogen. Common components containing active hydrogen include polyether polyols, polyester polyols, epoxy resins, hydroxy acrylic resins, etc. In these products, the addition of hardeners can not only improve the cross-linking degree and internal energy of the product, but also enhance the strength and weather resistance of the final product. Polyurethane hardeners have been widely used in fields such as adhesives, coatings, inks, etc.

Classification of polyurethane hardeners

For polyurethane hardeners, they can be classified into three categories: solvent based, water dispersible, and closed type.

Solvent based hardener

For most traditional products, solvent based hardeners are commonly used, which can endow the product with better strength, weather resistance, mechanical properties, etc.

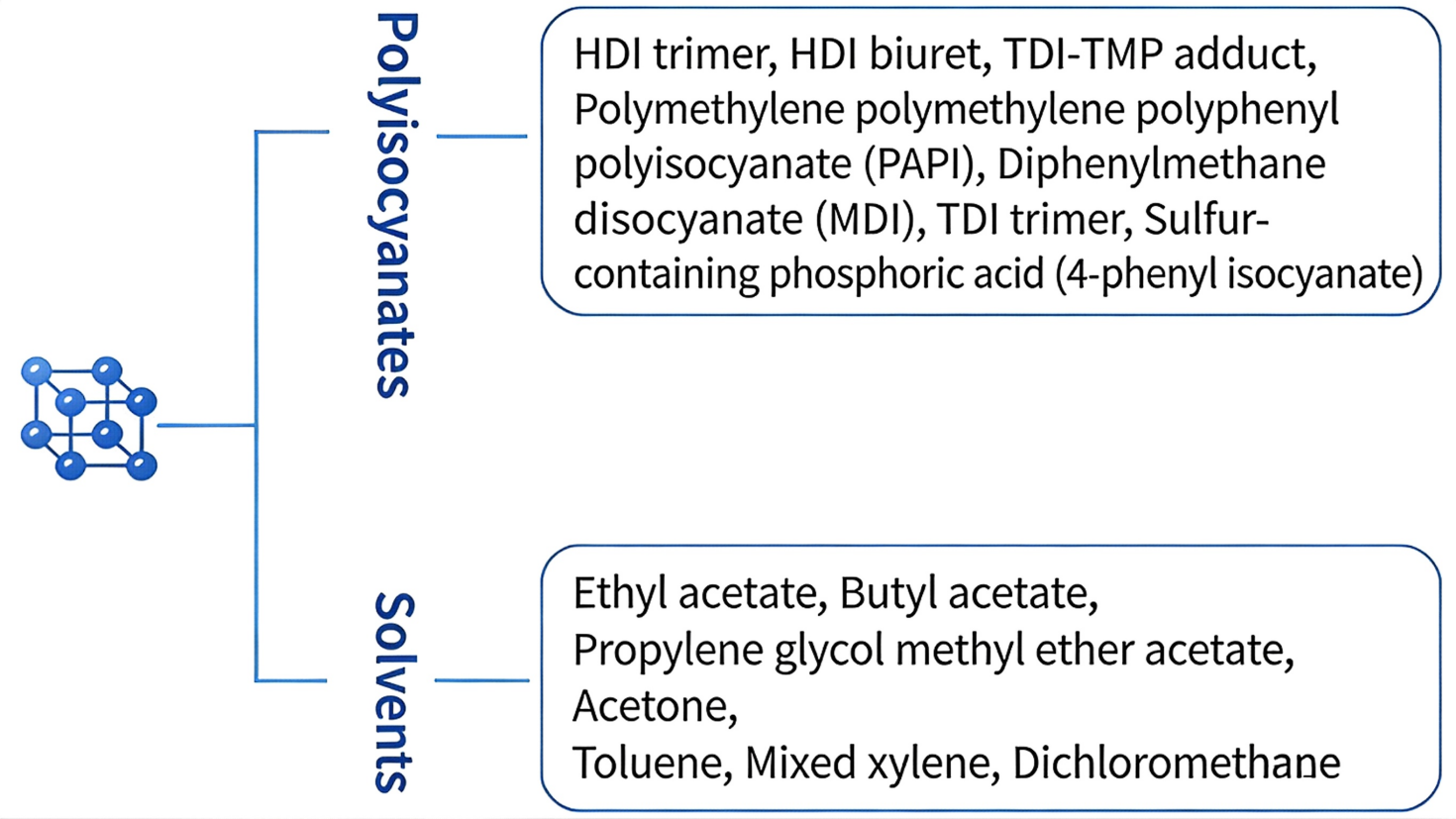

Common substance composition of solvent based hardeners

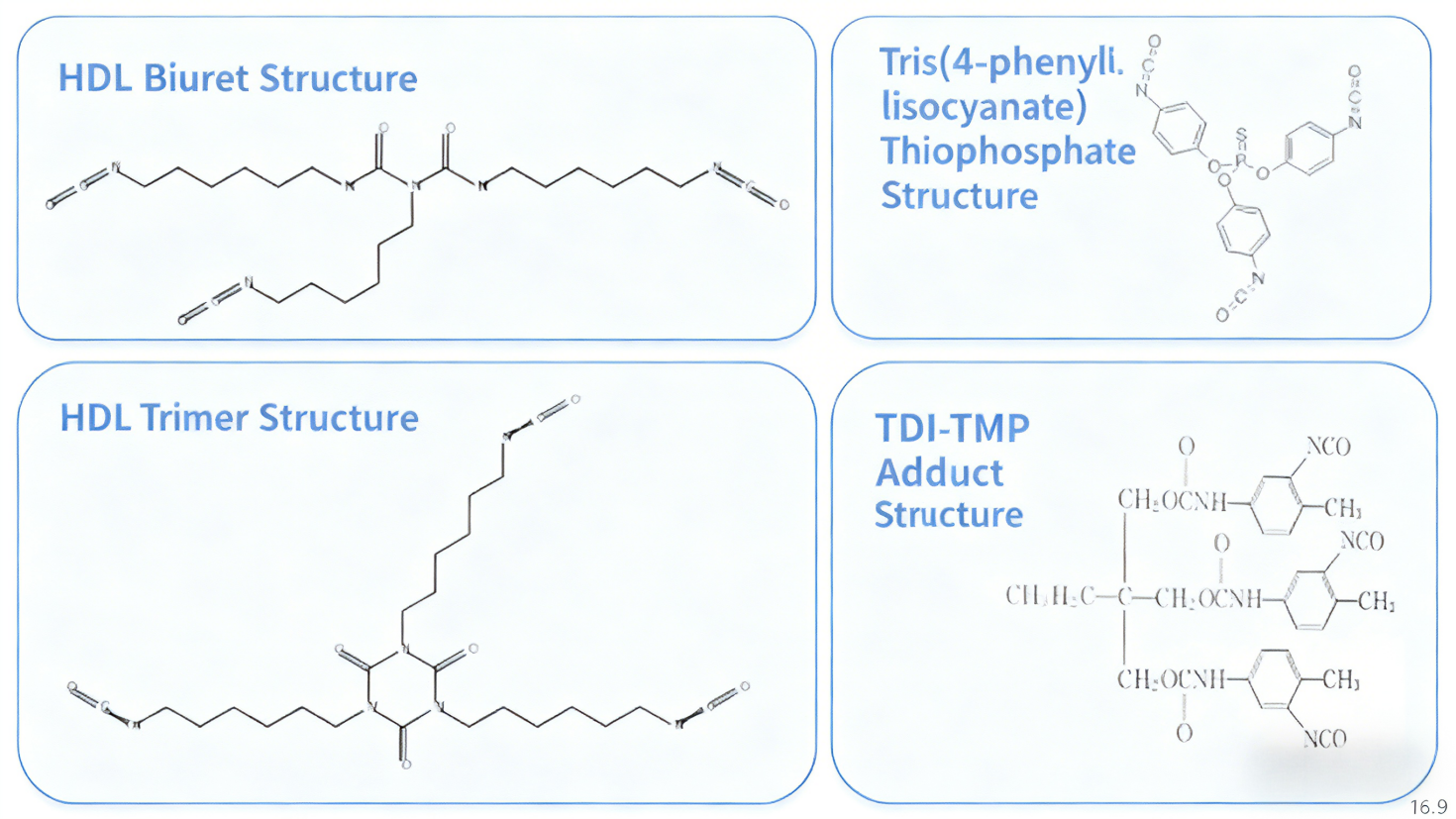

Structural formulas of some commonly used polyisocyanates

Water dispersible hardener

With the increasing awareness of environmental protection among people, water-based polyurethane materials are gradually receiving attention. In two-component waterborne polyurethane products, isocyanate components play a crucial role. The current common approach is to achieve dispersion in water by hydrophilic modification of isocyanates. The main methods of modification include non-ionic modification, anionic modification, and anionic nonionic modification.

Non ionic modification

Non ionic modification mainly involves hydrophilic modification of polyisocyanates using polyethylene glycol monomethyl ether (MPEG), polyethylene glycol (PEG), etc. The modified polyurethane hardener not only has a certain hydrophilicity, but also the remaining NCO groups are encapsulated, allowing it to remain stable in water for a period of time.

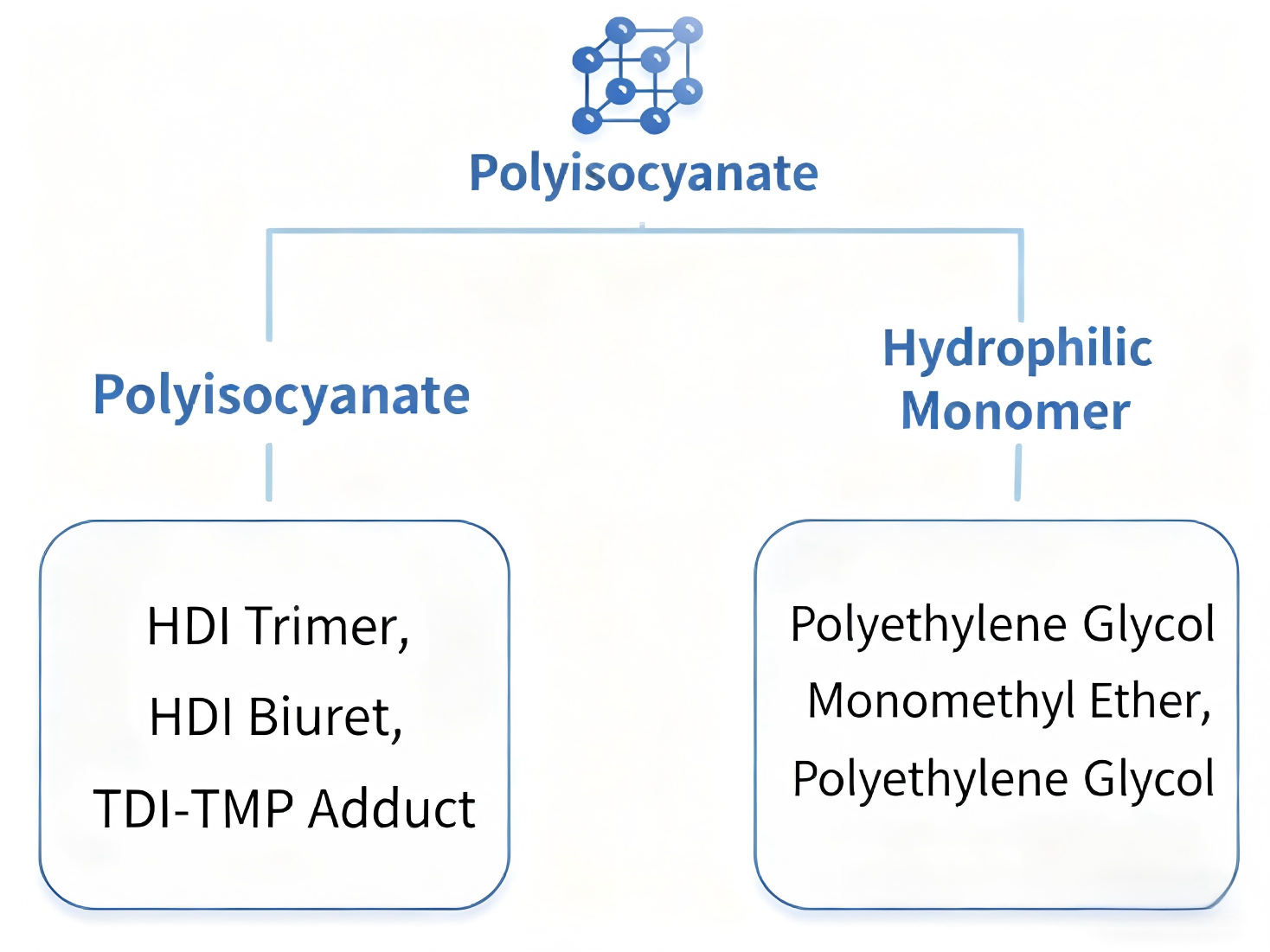

Common Composition of Non Ionic Modified Substances

Anionic modification

Hydrophilic polyisocyanates can also be obtained through ion modification. The usual ion modification methods include carboxylate modification, sulfonate modification, etc. Carboxylate modification generally uses dimethylolpropionic acid (DMPA), while sulfonate modification generally uses ethylenediamine ethanesulfonate and aminosulfonate, etc. They introduce carboxyl or sulfonic acid groups on the molecular chain to enable polyurethane hardeners to emulsify in water.

Common Composition of Anionic Modified Substances

Polyisocyanates: HDI trimer, HDI biuret, TDI-TMP adducts

Hydrophilic monomers: polyethylene glycol monomethyl ether, 3- (cyclohexylamine) -1-propionic acid, polyethylene glycol monomethyl ether, dihydroxymethylpropionic acid

Salting agents: N, N-dimethylcyclohexylamine, triethylamine

Negative non-ionic modification

At present, non-ionic modification is commonly carried out using polyethylene glycol monomethyl ether for modification, but the introduction of monomethyl ether can cause water resistance problems and crystallization tendencies. Although ionic modification can solve water resistance problems, it requires high pH of the solution. The mixed modification of anions and non ions can effectively overcome the above problems.

Common substance composition of anionic nonionic modification

Polyisocyanates: HDI trimer, HDI biuret, TDI-TMP adducts

Hydrophilic monomers: 3- (cyclohexylamine) -1-propionic acid, dihydroxymethylpropionic acid

Salting agents: N, N-dimethylcyclohexylamine, triethylamine

Closed polyurethane hardener

The NCO groups in the hardener components have high activity and can react with water in the atmosphere at room temperature to cause deterioration. In order to facilitate storage and reduce raw material loss, a sealing agent can be used to react with NCO to produce a stable closed hardening agent at room temperature.

Closed curing agents can be heated to restore their original isocyanate structure and react with hydroxyl containing components. The formula design idea is generally to introduce a sealing agent on the basis of the common solvent based and water dispersible polyurethane hardeners mentioned above, in order to block the excess NCO groups. The unsealing temperature of different sealants varies, and we can also choose different sealants according to specific usage scenarios. Common sealants and their unsealing temperatures are shown in the table below.

Common sealing agents and their unsealing temperatures

|

Sealant |

Release temperature/℃ |

|

Caprolactam |

175-200 |

|

Ethanol |

180-185 |

|

Methyl ethyl ketoxime |

140-150 |

|

Phenol |

140-145 |

|

3,5-dimethylpyrazole |

130-150 |

|

Acetone oxime |

130-140 |

|

Ethyl acetoacetate |

125-150 |

|

Diethyl malonate |

130-140 |

|

Imidazoles |

130-140 |

|

Sodium bisulfite |

50-70 |

Application of polyurethane hardener

With the rapid development of polyurethane, its hardener has also been produced and rapidly developed.

Polyurethane hardeners are applied in the fields of adhesives, printing pastes, and inks to improve bonding performance and enhance wash fastness; As an external crosslinking agent applied in wood coatings, paints, leather finishing agents, etc., it can maintain high gloss, improve hardness, enhance water resistance, solvent resistance and other properties.

In some baking paint systems, such as coil steel paint, closed polyurethane hardener is mostly used. After heating and unsealing, it solidifies, and the coating has better toughness, weather resistance, and scratch resistance after film formation.

In some high-quality furniture industries, such as matte wood paint, the clear varnish coating with an external matting agent has low transparency and poor resistance to media. And through the use of hardeners, the extinction effect can be achieved from the molecular structure. The same type of paint, combined with different structures of matte hardeners, can achieve the gloss we need.

In some food flexible packaging fields, solvent based aromatic polyurethane hardeners such as TDI-TMP adducts are mostly used. In recent years, researchers have been committed to developing low free NCO hardeners and alternative aliphatic polyurethane hardeners for food safety considerations.