Located in JiangMen City, Guangdong Province, our production base is a modern manufacturing complex with state-of-the-art facilities.

Located in Heshan City, Jiangmen, Guangdong Province, with convenient access to major transportation hubs including ports, airports and highways.

The production base covers an area of 63,914 square meters with modern workshops, R&D centers, testing laboratories and storage facilities.

Equipped with advanced automated production lines and precision testing equipment from leading international manufacturers.

Comprehensive safety management system and environmental protection facilities to ensure safe and sustainable production.

Our production base features multiple specialized workshops equipped with advanced manufacturing equipment

Automated Production Lines

Equipped with 8 automated production lines with a total capacity of 30,000 tons per year, featuring advanced control systems and precise metering equipment

8 automated production lines Precision metering systems PLC control systems

Innovation & Development

3,000 square meters R&D facility with advanced analytical instruments and pilot production equipment for product development and process optimization

30+ R&D engineers Advanced analytical instruments Pilot production lines

Testing & Analysis

State-of-the-art testing laboratory accredited to ISO/IEC 17025 standards, equipped with over 50 precision testing instruments

ISO/IEC 17025 accredited 50+ testing instruments Real-time quality monitoring

Warehousing & Distribution

15,000 square meters of storage space with temperature and humidity control systems, and a modern logistics management system

15,000 sqm storage space Temperature & humidity control Modern logistics system

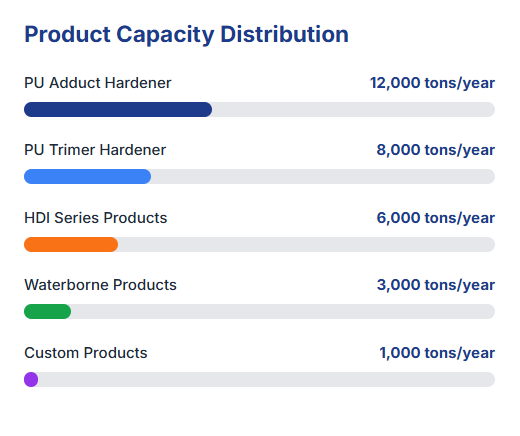

Our production base has a total annual capacity of 30,000 tons, with specialized production lines for different product series

Automated production lines with high efficiency and low energy consumption, ensuring competitive production costs

Strict quality control systems and advanced testing equipment ensure product quality consistency

Optimized production scheduling and sufficient inventory ensure quick delivery and short lead times

Flexible production lines that can be adjusted for different product specifications and custom requirements

All raw materials undergo strict inspection before entering production, including identity verification, purity testing, and impurity analysis

Real-time monitoring of production parameters and regular sampling during the production process to ensure process stability

Comprehensive testing of finished products including physical properties, chemical composition, and application performance

Products are only released after passing all quality tests and receiving approval from the quality control department

Regular review of quality data and implementation of continuous improvement measures to enhance product quality